Waste to Energy Systems

The designation of stuff we have used and discarded is being changed. As awareness of the environmental implications of waste generation is becoming more widely known, this material is now more commonly classified as a resource; the substrate for implementation of the circular economy.

The Organics Group offers a wide range of tried and tested equipment for the conditioning, handling, management, and monitoring of this resource, especially for its use as a fuel. The financial services we have access to can provide a cost-effective mechanism for realising projects that can fully appreciate its value.

Waste to Energy Systems

Waste is now more commonly classified as a resource; the substrate for implementation of the circular economy.

Pyrolysis

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Power can be derived from heat in many different ways. Heat travels in many forms. Flames are the most visible form of heat production but heat can be found where flames do not exist. Pyrolysis is the use of heat to break down biomass into its constituent gaseous components in the absence of combustion.

The pyrolysis technology offered by Organics involves the use of heat in the complete absence of air. Without air combustion is not possible.

The resultant reactions are therefore clean and complete, leading to a maximisation of power production in the form of Volatile Organic Carbons. These are the re-formed biomass constituent components now present as a gas.

With the complete absence of air, toxic products of partial combustion, such as dioxins and furans, cannot be formed.

Key Features

- Can be employed for the pyrolysis of biomass using clean heat.

- No combustion of flames are involved in the process.

- Low emissions resulting from the absence of air during thermal degradation.

- Drying in the absence of air maximises VOCs.

- Machines are compact and efficient.

- Low running costs reduce operational expenses.

- Long life-cycle of equipment between overhauls.

- Extremely cost-effective for small and large-scale waste disposal

- Can be used for the destruction of hazardous and clinical waste.

Download datasheet

Send download link to:

Gasification

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Biomass gasifiers operate by heating biomass in an oxygen-starved environment until the biomass breaks into its constituent chemical components. The process requires the input of heat energy for the endothermic chemical reaction to proceed that splits the molecules apart.

Gasification with air produces a low-Btu gas, with a heating value about one-fifth that of natural gas. Indirectly heated gasification and oxygen-blown gasification produces a medium-Btu gas, with heating values as much as one-half that of natural gas. The product gas is suitable for fuelling advanced power systems that require clean, gaseous fuels.

Organics has developed and proven its own in-house technology for the efficient gasification of varied biomass streams. Of particular interest is Municipal Solid Waste, although many types of organic waste are suitable for use with this technology to produce energy.

Such waste is at present a public liability, causing difficulties for transfer, handling and long-term disposal. The Organics gasification system is designed to accept a broad range of organic waste consistencies. This is an essential pre-requisite for systems designed to gasify Municipal Solid Waste.

Key Features

Key features

- maximise energy production from biomass waste streams

- low emissions, well within environmental limitations

- ability to accept a wide variety of biomass feed streams

- size range up to 300 tonnes per day

- vendor finance and operate options a speciality

Advantages

- Immediate conversion of biomass waste to energy

- Waste reduction to ash for landfilling

- Maximises existing landfill capacity

- Integrated management options to combined wet wastes and dry wastes into a single energy park

- The absence of excess air in the thermal reduction process prevents the formation of harmful pollutant gases

Download datasheet

Send download link to:

Hydrogen

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The technology for separating ammonia from wastewater and using it as a source of hydrogen is still in its infancy, although several projects already underway are proving the robustness of the technique.

Ammonia is a form of energy storage that allows for renewable energy to be stored in a supply-based and flexible manner, and therefore helps to balance energy supply and demand.

Ammonia recovery from wastewater using the Organics thermal recovery system offers the opportunity to utilise waste heat and generate additional revenue from the sale of ammonia related products offering a profitable alternative to conventional denitrification systems which are energy intensive, often require addition of expensive reagents and destroy ammonia.

In the article accompanying this section, Robert Eden, the CEO of the Organics Group, discusses the benefits of this new technology.

Advantages

- Hydrogen can be used as an energy source in, for example, fuel cells to drive forward hydrogen-powered transport, or as means to produce synthetic fuels

- Recovery of a resource from an inflow that has traditionally been regarded as an operational disadvantage

- Hydrogen is an energy storage medium that can be used to offset the use of fossil fuel for power generation

- Hydrogen is recovered from ammonia that has been separated from wastewater

- Ammonia is far more stable than hydrogen and can be easily and safely transported.

Download Article

The Emerald Option as published in the World Fertilizer Magazine, December 2020

Send download link to:

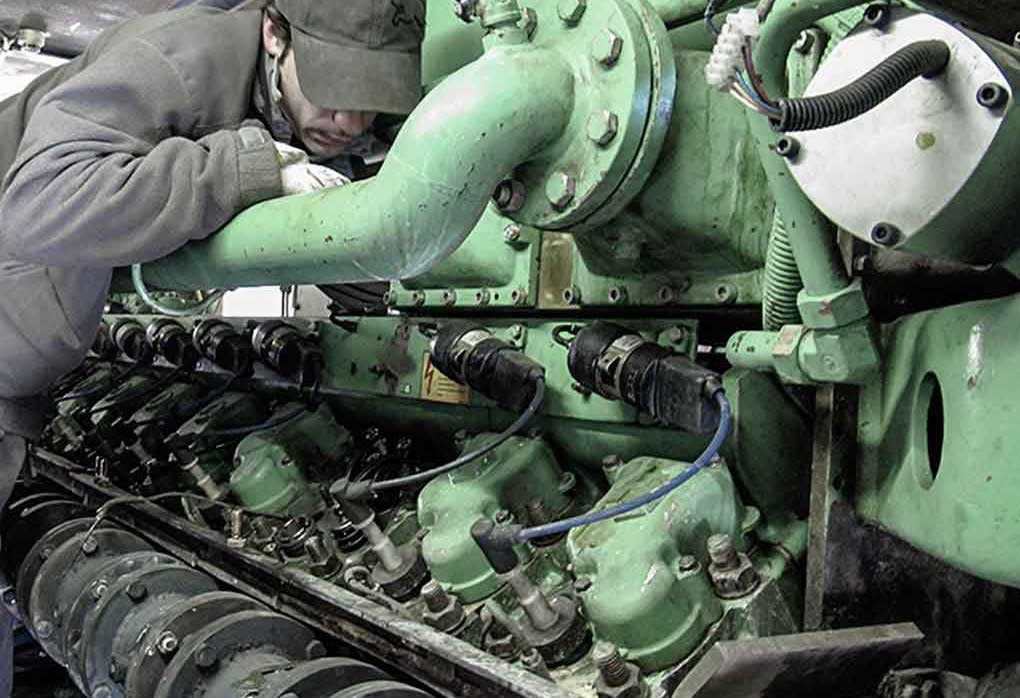

Operation and Maintenance

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Operation and maintenance is the core aspect of any renewable energy project. Without a properly costed and resourced operation and maintenance plan, any project involving complex engineering updates is doomed to failure.

The Organics Group has been involved in the fabrication, supply, installation, commissioning, and post-installation operation and long-term maintenance for over thirty years. We, therefore, have a long track record of ensuring that the equipment we supply continues to provide reliable service for many years, even after the amortization of any project finance.

We pride ourselves on the skills and dedication of our maintenance teams and always recommend that a comprehensive maintenance plan should be considered as part and parcel of the initial specification for any large-scale environmental engineering project.

Advantages

- Maintenance plan considered during the initial planning stages of the project

- Planned maintenance schedule following all manufacturers’ recommendations

- Highly trained technicians available as required

- If necessary, 24-hour service can be implemented

- Can be included in the financing of the project

- Emergency service to cover unscheduled breakdowns

- Stoppage time minimised ensuring that commercial viability is protected.

Consultancy Services

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Resource Assessment

Organic material within landfill sites is a source of methane, a gas that has been shown to be one of the most potent gases in terms of its potential for climate change. However, methane is also one of the most potent elements for generating power. Therefore, its properties for use as a fuel, either for power generation or vehicle fuel, are increasingly being taken advantage of to displace the use of fossil fuel to do the same job.

Estimation of the size of the resource is a task which not only delimits the extent of environmental control but also defines the budget required for minimising its impact and maximising the benefit obtained.

The principal objective of any study is to establish a fully defined solution that identifies the engineering and finance options required to achieve the clients’ objectives.

Turnkey Solutions

Turnkey solutions provide clients with a premium package that ensures lifetime optimisation of projects and maximisation of opportunity.

The Organics Group is able to provide a complete package for the realisation of a project and, once it is completed, transfer it to the client as an operational unit.

The company has essential experience in all aspects of project management to ensure that projects are delivered on time, within budget, and to specification.

With more than 30 years of experience in the delivery of projects related to environmental control, as well as continually innovating in the field of renewable energy solutions, we are confident our team can provide the correct solution for any environmental challenge.

Finance and Operation

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The management of environmental control projects on an ongoing basis can be a complex, unexpectedly costly, and time-consuming activity.

It is often the case that project management companies, for example, those who manage landfill sites, may not wish to have key management efforts diverted from their core business to activities that are not considered part of their customary business model.

Passing such a responsibility to a specialist company makes it possible to remove the threat of penalties accruing from system failures as well as facilitating the establishment of a clear financial forecast as a basis for the management of the issues involved.

Advantages

- No capital investment

- No operational staffing requirement

- All design, construction, and operational issues undertaken by a specialist team having all the relevant skills

- Input from the Client’s management staff is significantly reduced during the design and construction period

- Input from the Client’s project management and operational staff is minimised during the operational stage of the project

- The Client’s staff is released to concentrate on the core activity of the company

- Minimal concern/liability for plant operations and treatment performance.

Download datasheet

Send download link to:

Equipment Supply

The Organics Group supplies a wide range of environmental equipment, from down-borehole pumps for leachate extraction to flarestacks for burning waste biogas, to plant for the separation and recovery of ammonia.

For over thirty years and across more than 300 projects, the Organics Group has built a body of knowledge related to the demands of environmental engineering that has contributed to the company being a leader in the field.

Experience, innovation, and a strong reliance on expert technicians and engineers ensures that the Organics Group is able to supply solutions for the most challenging of environmental situations related to environmental protection, whilst at the same time providing a reliable service on which our customers can depend.