Anaerobic Digestion Technology

anaerobic digestion of Wastewater

Anaerobic digestion involves the breakdown of organic waste by bacteria in an oxygen-free environment. It is commonly used as a waste treatment process but also produces a methane-rich biogas which can be used to generate heat and/or electricity.

For more information, check our our user-friendly questionnaire if you would like some technical assistance.

ANAEROBIC DIGESTION TECHNOLOGY

If you have a requirement for the treatment of wastewater with particular regard to ammonia, please contact us. We will give your communication the highest priority.

Anaerobic Digestion; a Cost-Effective Solution

Anaerobic Digestion (AD) involves the breakdown of organic waste by bacteria in an oxygen-free environment. It is commonly used as a waste treatment process but also produces a methane-rich biogas which can be used to generate and/or electricity.

In simple terms, AD equipment consists of a heated digester tank, a gas holder to store the biogas, and a gas-burning engine/generator set in the case the energy is to be produced by using the biogas as a fuel. The organic waste is broken down in the tank, and up to 60% of this waste is converted into biogas.

The Organics anaerobic digestion system has been designed to be both high-rate and to manage refractory solids.

Anaerobic Digestion

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

AD equipment consists, in simple terms, of a heated digester tank, a gas holder to store the biogas, a system to process the biogas to ensure it can be used in mechanical process equipment, and an engine or generator set to produce heat or energy.

The organic waste is broken down in the tank, and up to 60% of the mass is converted into biogas. The rate of conversion depends on the temperature of the process and the composition of the waste.

Biogas typically has a calorific value of typically between 50 – 70% of natural gas and can be combusted directly in modified gas engines or natural gas boilers.

Organics has designed systems to be both high-rate and capable of managing refractory solids.

Advantages

- AD is a well-proven technology that can be installed and run successfully for many years.

- Production of biogas without the creation of issues related to air pollution.

- AD can reduce and control odour and attention of pests.

- Waste is minimised and wastewater can be fully treated for release to the environment.

- There is a social net benefit by avoiding greenhouse gas and producing renewable energy.

- AD is a relatively low-technology solution for treating waste and wastewater. It does not require sophisticated control and management to be operated successfully.

- Commercial by-products can include biogas, compost, liquid fertiliser, ammonia and energy.

Download the datasheet

Send download link to:

CSTR technology

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Active contact between the feed and the existing biomass is maintained whilst preventing internal stratification and temperature gradients. The mixing action also minimises the formation of a scum layer and the settlement of sludge solids.

Organics is equipped to supply individual components within a complete system or all of the components required to make up a complete system.

Principal Objectives of AD

The objectives of a project designed to recover energy from processing waste and wastewater are:

- The installation of an anaerobic digester which will generate and capture waste gases and so reduce the emission of greenhouse gases

- Reduction of odours and harnessing energy in the form of methane

- Generation of renewable electricity to offset the use of fossil-fuels

- Improvement the efficiency and reduce the carbon footprint of wastewater treatment.

Download the datasheet

Send download link to:

AD of Cattle Manure

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Perhaps one of the more notable aspects of cattle manure digestion is the range of potential biogas production figures that may be achieved from this apparently similar substrate. As well as a wide variety of differing breeds, with different rates of manure production, different moisture contents and different volatile solids composition, there are also local factors within waste arisings that impact biogas productivity. These include the type of bedding employed, the method of collection of the manure, the extent of dilution during collection, the time between formation and use in an anaerobic digester and last, but not least, the diet of the cattle and the extent of feeding.

It is, therefore, either a question of carrying out site-specific waste stream analysis and testing, including the all-important Biochemical Methane Potential (BMP) test, or accepting that performance results may be unpredictable within a range of possibilities.

Organics is equipped to supply individual components within a complete system or all of the components required to make up a complete system. Organics has been active in this sector since 2002 and has a wide experience with all elements of such systems, from equipment design, instrumentation set-up for CDM compliance and CDM compliant gas flaring to gas production technologies as well as energy generation using engines operating with biogas.

Advantages

- AD is a well-proven technology that can be installed and run successfully for many years.

- Production of biogas without the creation of issues related to air pollution.

- AD can reduce and control odour and attention of pests.

- Waste is minimised and wastewater can be fully treated for release to the environment.

- There is a social net benefit by avoiding greenhouse gas and producing renewable energy.

- AD is a relatively low-technology solution for treating waste and wastewater. It does not require sophisticated control and management to be operated successfully.

- Commercial by-products can include biogas, compost, liquid fertiliser, ammonia and energy.

Download the datasheet

Send download link to:

Waste as a Resource

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Every time the price of oil peaks, the issue of waste as an energy resource becomes a major preoccupation with governments, businesses and individuals. The pressing need is to escape the impact of potentially crippling increased costs.

There is no doubt that waste biomass streams are commercially attractive. This is, in fact, the case in many situations where the price of oil has already been sufficient to make consideration of alternative fuels a commercially attractive proposition.

Waste can come in many forms suitable for energy recovery. The processing of agricultural products, such as tapioca, palm oil, rice and coconuts leaves significant quantities of solid and liquid effluent which can be processed to produce energy.

Project Route

All projects follow a similar administrative route from initial specification through to handover. Organics has developed a project delivery structure over many years that ensures reliable completion and quality control whilst maintaining specification requirements, and time-schedules.

Specification

Define a clear statement of the design parameters.

Design

Once all the information has been gathered, the design will reflect the requirements of the project.

Procurement

Establish delivery schedules.

Fit-out and Installation

Fit out will be on site after delivery of all components and overseen by a qualified engineer.

Commission and handover

Established commissioning schedules are designed and followed to ensure correct funcion.

Service Support

Support can range from supply of spare parts and advice to regular servicing or complete operational management.

Download our datasheet

Send download link to:

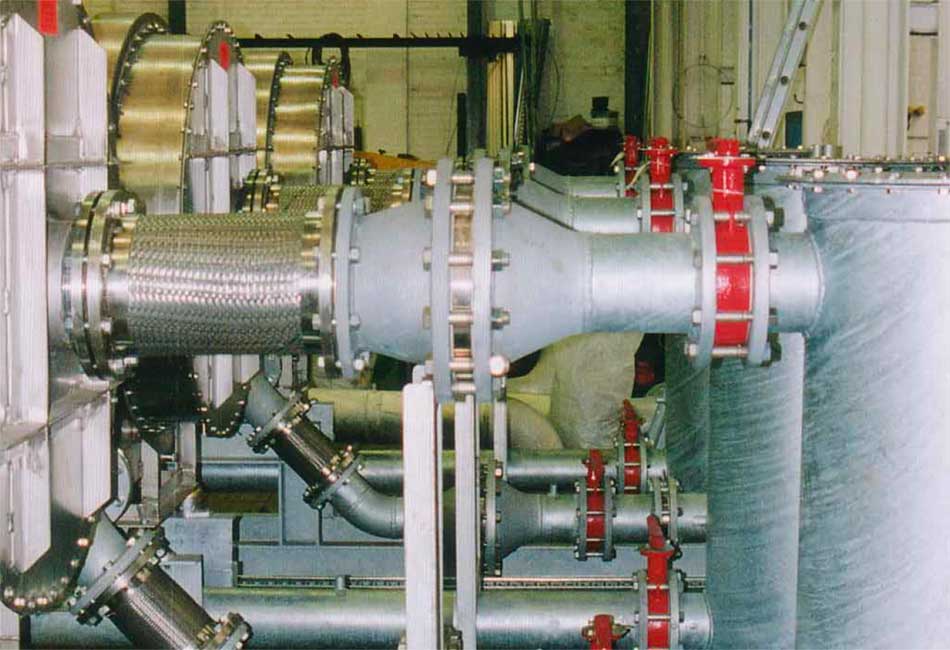

Gas Pumping Set

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The absolute requirement for a fuel skid is long-term reliability.

Units designed, manufactured and supplied by Organics employ tried and tested technology for landll gas pumping applications where unnecessary downtime has immediate ramifications in terms of revenue generation and, it is fully recognised, must be avoided.

It is now well acknowledged that landll gas is a unique fuel. It possesses characteristics that are not matched by any other similar fuel gas, such as natural gas or biogas from anaerobic digesters.

For this reason a landll gas fuel skid must be built specifically for this application. Of particular note are the high-levels of moisture drop out and the possibility of a wide range of potentially corrosive trace gases. These range from halogens to ammonia and mercaptans.

Key Features

- High reliability

- Optional air blast cooling and refrigerated chilling for dew-point management.

- Site-specific design

- Automatic moisture removal systems for collected condensate

- Optional speed controllers for pressure and flow fine tuning as well as power saving

- A range of materials to suit specific applications

- Integrated control systems with facilities to link to main control centre

Download the datasheet

Send download link to:

H2S Treatment

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The anaerobic digestion of organic matter produces methane and carbon dioxide. It can also lead to the production of other trace gases, such as hydrogen sulphide. As well as being a health and safety hazard, hydrogen sulphide can cause serious corrosion-damage to metal components in engines, burners and boilers. Therefore, it must be reduced to safe levels prior to the use of such gas in any commercial or long-term application.

Hydrogen sulphide can be removed from gas streams by means of several established technologies. The main advantage of a bio-scrubber is that in most circumstances there is no cost incurred for chemical-additions.

The bacteria involved (genera thiobacillus) are ubiquitous. As long as the correct environmental conditions are maintained, the bacteria will function reliably and predictably in the removal of hydrogen sulphide from gas streams.

Ket Features

- Prevent corrosion in plant and equipment that can be brought about by hydrogen sulphide

- Prevent emissions of sulphur dioxide

- Remove health hazards that can result from high concentrations of hydrogen sulphide

- Remove noxious odours

- Organics gas bio-scrubbers meet all environmental standards for removing hydrogen sulphide.

Download our datasheet

Send download link to:

Treatment of POME using Anaerobic Digestion

The anaerobic digestion of wastewater is a tried and tested technology that results in an efficient control and management of waste effluent from many industrial processes.

Palm oil is notorious for its damaging effects on the environment. The treatment of palm oil mill effluent POME can not only reduce the carbon footprint of the industry but ensure that it moves towards a more sustainable future.