Pyrolysis

Skid mounted waste disposal

Pyrolysis of organic waste material has the potential to be an important link in the circular economy. The technology offers a sustainable approach to converting organic materials into valuable products, including biochar. It helps to reduce waste, particularly agricultural waste, sequester carbon, improve soil health, and reduce reliance on fossil fuels.

PYROLYSIS

Pyrolysis of organic waste material has the potential to be an important link in the circular economy and offers a sustainable approach to converting organic materials into valuable products, including biochar.

The Pyroclast®

The PYROCLAST® pyrolysis unit is designed for final waste disposal. This is its primary intent. Energy recovery can easily be added, in the form of an Organic Rankine Cycle power unit, although this is not a component in the standard package.

The technology involved is not comparable to incineration, where flames and burning zones need to be controlled. Pyrolysis occurs in the absence of air and, more specifically, oxygen. It is a thermal degradation process, equivalent to melting, where solid matter is converted into its gaseous form without the presence of flames.

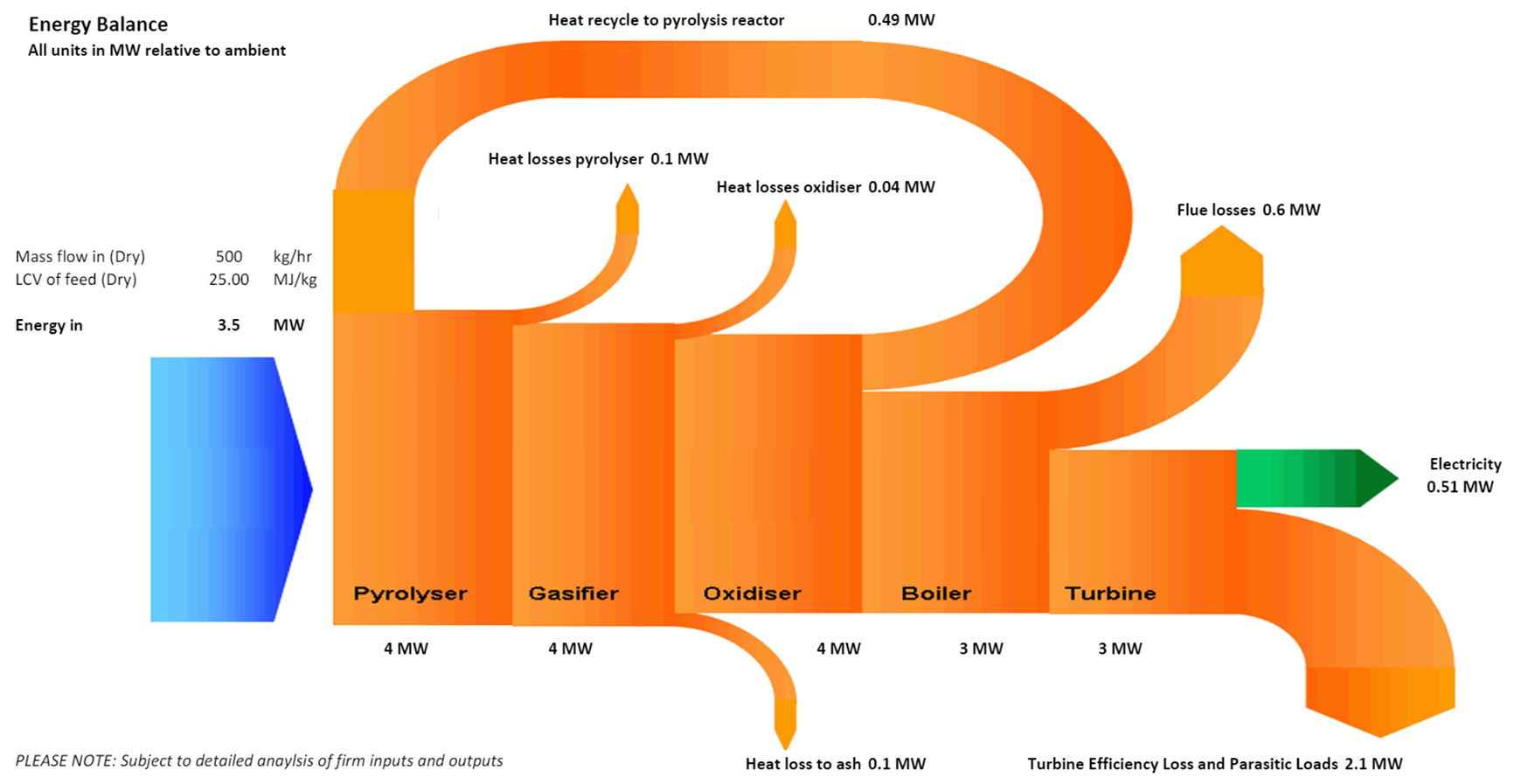

ENERGY PRODUCTION

The PYROCLAST can be installed into buildings for long-term applications such as for use as the primary disposal method in small communities. The unit is flexible in that it can be run in several modes such as for extended operation campaigns, on a continuous basis, or simply as and when required.

The output from this unit is ash and heat. For most biomass and municipal solid waste applications, the ash is non-toxic and may be used in various industries as a bulking agent. Heat may be used or dumped. Ideally, it should be employed but this is not always commercially practical.

Where preferred, the gasification phase of carbon char may be omitted. This will result in the production of a carbon char which can be used to condition soil, as depicted in the Sankey Diagram below.

General Information

The Pyroclast Range is designed around equipment sizes that can be built into ISO containers for ease of shipping and deployment. The Pyroclast is, therefore, a highly mobile unit for waste disposal in an environmentally sound and thermally efficient manner.

The Pyroclast may also be installed into buildings for long-term applications, such as for use as the primary disposal method in small communities. It may be run in extended operation campaigns, operated on a continuous basis or simply as and when required.

Size Range

Pyroclast I: 6 to 20 tonnes (wet) per day 4 to 12 tonnes (dry) per day

Pyroclast II: 6 to 40 tonnes (wet) per day 4 to 24 tonnes (dry) per day

Key Features

Availability:

Normal operation: 85%

Preventative maintenance: 90%

Moisture content:

Moisture will reduce the thermal energy available. The unit is designed for 20% moisture content (wet basis) but can take larger amounts.

Waste types:

– Biomass of many varieties

- Sorted municipal solid waste

- Clinical waste

- Thermally degradable hazardous waste

Typical Applications

Primarily designed to address waste disposal, the PYROCLAST can also produce heat and energy. Using a suitable feedstock, such as RDF, or green waste, the PYROCLAST is ideal for handling small amounts of waste. If larger capacity is required, the units can either be installed in a building or more modular units can be added to the process chain.

A PYROCLAST applied to raw municipal solid waste requires front-end sorting equipment to prepare the feedstock for the pyrolyser. This equipment normally involves rotary screens and other such machinery, to classify the waste stream according to its make-up and the requirements of the overall process.

When applied to landfilled waste, the PYROCLAST front- end can be much simpler, involving a fully mechanised process of one or two rotary screens.

General Information

The Pyroclast Range is designed around equipment sizes that can be built into ISO containers for ease of shipping and deployment. The Pyroclast is, therefore, a highly mobile unit for waste disposal in an environmentally sound and thermally efficient manner.

The Pyroclast may also be installed into buildings for long-term applications, such as for use as the primary disposal method in small communities. It may be run in extended operation campaigns, operated on a continuous basis or simply as and when required.

Size Range

Pyroclast I: 6 to 20 tonnes (wet) per day 4 to 12 tonnes (dry) per day

Pyroclast II: 6 to 40 tonnes (wet) per day 4 to 24 tonnes (dry) per day

Key Features

Availability:

Normal operation: 85%

Preventative maintenance: 90%

Moisture content:

Moisture will reduce the thermal energy available. The unit is designed for 20% moisture content (wet basis) but can take larger amounts.

Waste types:

– Biomass of many varieties

- Sorted municipal solid waste

- Clinical waste

- Thermally degradable hazardous waste

Typical Applications

Primarily designed to address waste disposal, the PYROCLAST can also produce heat and energy. Using a suitable feedstock, such as RDF, or green waste, the PYROCLAST is ideal for handling small amounts of waste. If larger capacity is required, the units can either be installed in a building or more modular units can be added to the process chain.

A PYROCLAST applied to raw municipal solid waste requires front-end sorting equipment to prepare the feedstock for the pyrolyser. This equipment normally involves rotary screens and other such machinery, to classify the waste stream according to its make-up and the requirements of the overall process.

When applied to landfilled waste, the PYROCLAST front- end can be much simpler, involving a fully mechanised process of one or two rotary screens.