Gas Monitoring & Equipment Supply

A growing concern for the environmental protection, and the requirement for ensuring the safety of everyone working and living near decomissioned landfill sites, or contaminated land has resulted in an increased demand for high-quality equipment to undertake a variety of tasks ranging from monitoring of emissions to control of releases of biogas from decomissioned landfill sites.

Organics provides a wide range of equipment for monitoring and ameliorating uncontrolled emissions of biogas, as well as equipment for environmental protection and the recovery of resources.

Gas Monitoring & Equipment Supply

Organics provides a wide range of equipment for monitoring and ameliorating uncontrolled emissions of biogas, as well as equipment for environmental protection and the recovery of resources.

Feed Gas Analysis Equipment

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

On-line feed gas equipment will typically measure methane, carbon dioxide and oxygen. On occasion it may also include hydrogen sulphide, and carbon monoxide.

An important part of managing a gas collection system is to understand how the gas quality of a landfill site is varying with operating conditions and time.

Landfill gas is a difficult gas to monitor reliably. It tends to be saturated with moisture, leading to condensation in working parts, as well as to contain a wide range of contaminant gases that can be both cross-sensitive to inappropriate sensors and damaging to others which are not suitable for the environment.

The systems offered by Organics include feed gas filtration, feed gas pre-heating to avoid condensation and water flood-protection.

Key Features

- on-line monitoring of methane, carbon dioxide and oxygen

- pre-heating of sample gas to avoid formation of condensate

- sample gas filtration

- in-built dewatering systems

- water flood-protection measures and alarm notification

Download datasheet

Send download link to:

Exhaust Gas Analysis

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

With increasing environmental awareness and a tightening of statutory controls, the monitoring of exhaust gases emitting from landfill gas flaring and utilisation systems is becoming an increasingly important element of well-managed facilities.

The recently prepared UK Environment Agency standards set limits for Carbon Monoxide, Oxides of Nitrogen and Unburned Hydrocarbons. The two former gases can be measured with relative ease. The latter is not yet available at a realistic price, monitoring in the ranges required. Exhaust gas emissions are quoted as normalised to a standard oxygen content, typically 3% in the UK, so it is also necessary to monitor oxygen content.

Other gases that may be monitored include Hydrogen Sulphide, Sulphur Dioxide and Carbon Dioxide, although these have limited relevance in the exhaust from landfill gas combustion equipment.

Key Features

- on-line monitoring of exhaust gas quality

- datalogging of results for trend analysis

- systems designed specifically for sequential sampling

- multi-point sampling systems supplied on a design and build basis

Environment Agency Standards Compliance limits

To ensure that flare systems are operating correctly they should not exceed the following emission concentrations when referred to Normal Temperature and Pressure (NTP=0oC and 1013 mbar) and 3% oxygen:

- Carbon monoxide (CO)- 50 mg/Nm3

- Oxides of nitrogen (NOx) – 150 mg/Nm3

- Unburned hydrocarbons – 10 mg/Nm3

Requirements for monitoring regimes to be applied to enclosed flares

Guidance is given as to the level of monitoring which should be recommended and the acceptable methods that may be employed. Easily accessible, safe and functional monitoring/sampling points should be retrofitted to enclosed flares as appropriate in situations where they are currently absent. Gas concentrations should be analysed annually to determine trace gases.

Download datasheet

Send download link to:

Ambient-air line coolers

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Process gas and liquid cooling using ambient air blast coolers

- Reduce line temperatures to ambient plus 10oC

- Gas and liquids

- Stand-alone or as part of a system

- Materials to suit application

Key Features

Compression of gases can often lead to line temperatures being unacceptably high. Most plastic pipeline material, for example, will be damaged by excessive temperatures.

The Organics ambient air line cooler range can be installed into systems where temperatures approximately 10oC above ambient air will be adequate to meet process specifications.

Size range

Line-coolers can be supplied for units delivering gas in the size range 500 cubic metres per hour to 10,000 cubic metres per hour. Larger flows can be accommodated upon request. Temperatures can be reduced from several hundred degrees centigrade to near ambient temperatures.

Application

The protection of pipeline and downstream processes from excessive temperatures is the primary point of application of this technology. It is often the case, for example, that the feed-gas to an engine may have permitted maximum and minimum temperature requirements.

As well as having the facility to cool gases it may, in such a case, be a requirement to heat the gas in periods of exceptionally low temperature. Where this is a requirement, the Organics ambient air line-cooler can be fitted with a optional line-heating facility.

Download datasheet

Send download link to:

H2S Scrubbers

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The Anaerobic digestion of organic matter produces methane and carbon dioxide. It can also lead to the production of other trace gases, such as hydrogen sulphide. Hydrogen sulphide can be a health and safety hazard. The gas has an unpleasant odour and can cause the rapid corrosion of carbon steels.

Hydrogen sulphide can be removed from gas streams by means of chemical oxidative scrubbing. Such scrubbers employ water-based reagents containing oxidants such as sodium hydroxide, sodium hypochlorite, potassium hydroxide and ethanolamines. Each chemical oxidant has its advantages and disadvantages for specific applications.

Key Features

- Removes noxious odours

- Prevents corrosion in plant and equipment

- Prevent emissions of sulphur dioxide

- Remove local health hazards from the atmosphere

- Meets all environmental standards for hydrogen sulphide control

Download datasheet

Send download link to:

Odour Control

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Odour management and control is becoming increasingly important as more landfill site and contaminated land is being returned to public use. But the measurement and control of odour is a complex and frequently frustrating concern as the complex nature of the elements involved in odour are not always treatable by a single method.

Different people have widely differing responses to odour, and the sensitivity in any particular person usual descreases with age, whether someone smokes, or has had prior exposure to odour.

The Organbics Group has wide experience in the identification of odour sources, and has designed many systems to ensure a remedy. There are a wide range of methods that can be employed, all of them requiring careful initial assessment.

The Odour Trail

The Route to Treat Odour

i. Data Collection

ii. Source identification

iii. Source analysis

iv. Solution design

v. Solution installation

There is a clear route to ensuring that odour is identified, and the most appropriate solution applied. Data collection and analysis is essential to ensure that all the sources of odour have been identified.

It must be remembered that odour management can be a subjective exercise as the sensitivity of individuals to odour is wide-ranging and complex.

Download datasheet

Send download link to:

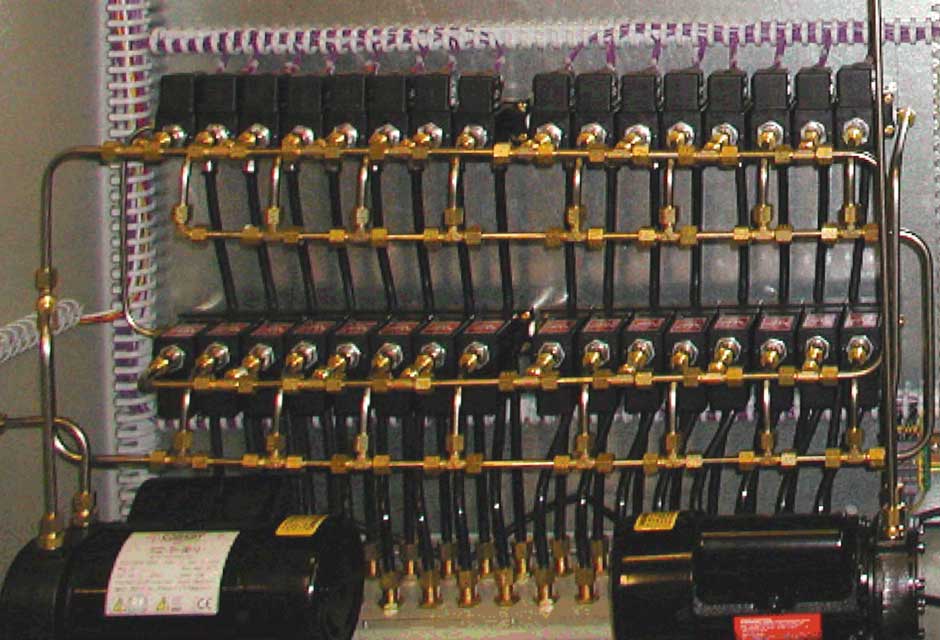

Distributed Monitoring

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Gas sampling systems for buildings and field migration protection systems

- Multi-gas systems available

- Fully automated operation

- Data logging and data analysis

Key Features

A distributed monitoring system extracts sample gas from particular locations around a site, passes them back through a series of small-bore pipe network, to a gas analysis suite where the target gases are measured and the readings logged for later analysis.

Where target gases exceed set trigger levels alarms are raised, either directly by means of a bell or flashing light, or remotely via the telephone network.

Size range

There is no limit to the number of points which can be monitored by a distributed monitoring system. Organics has installed one which covers over twenty buildings with up to thirty-two points per building.

Typical Application

Distributed Monitoring Systems can be of use in monitoring any atmosphere which may present a hazard to human health. This includes ambient air systems where oxygen depletion may occur, to buildings located on landfill sites where elevated levels of methane may result in an explosive mixture.

There are many other uses for such systems including, for example, monitoring carbon dioxide levels in greenhouse complexes or VOC levels in print rooms.

Download datasheet

Send download link to:

The Syclone®

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The Organics stipper/scrubber unit, the Sy-clone®, is designed for use in a chemical process environment to accomplish the following:

- Remove the need for packing

- Reduce the need for internal cleaning

- Reduce the height requirements

- Improve efficiency

The technology has been widely demonstrated as being viable and reliable.

Compact gas cleaning and liquefaction systemscan be employed to take such sources and convert them into a cryogenic liquid fuel that may be stored in bulk and dispensed in measured quantities.

The Organics Group offers mobile liquefaction units ranging in size from 2 tonnes per day to up to 10 tonnes per day, a system that is particularly flexible for sources of gas that may be declining or unstable in production.

Key Features

- No plates or packing required during operation

- High-impact contact between liquor and gas

- Maximise plant performance for a given duty

- High mass transfer rates to footprint area ratios

- Large units may be constructed as modular units

- May be skid-mounted for many applications

- Leads to significant savings in maintenance

- Highly resistant to blockage

Download datasheet

Send download link to:

Stranded Gas Installations

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

A stranded gas well is one where natural gas has been discovered, but the gas remains unusable for either physical or economic reasons. Gas that is found within an oil well is conventionally regarded as associated gas and has historically been flared.

A gas well can be economically stranded for one of two reasons: The well may be too remote from a market for natural gas, making construction of pipelines prohibitively expensive. Or the reserve may be in a region where demand for gas is saturated, and the cost of exporting gas beyond this region is excessive. Such wells are the most likely to be tapped in the future when existing sources begin to deplete.

Liquefied Natural Gas demand is increasing rapidly with consuming countries diversifying supply sources for energy security and to tap markets inaccessible by pipeline. Small-to-medium-scale LNG plant demand is increasing to develop gas from associated reserves and remote locations for distribution and vehicle fuel use.

Key Features

- Stranded gas in relatively small quantities may be recovered commercially.

- A typical installation may produce as little as 20 to 40 tonnes per day or methane and still be viable.

- 20 tonnes per day can generated approximately 4.5MW of electricity.

- Stranded gas is often found where oil-drilling recovered only gas and the gas could be moved commercially to the point of use.

- Gas originating in remote location may be cryogenically separated and liquefied before transport.

Download datasheet

Send download link to:

Activated-air Units

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

By means of a high-voltage applied to an ultra violet light generating, catalytic wire mesh, molecules in ambient air are split and energised, converting the moisture and air into a ow consisting of a mixture of unstable atoms, ions and radicals, with elevated electron activity levels. These Activated Air molecules may then be injected into a gas carrying target compounds. The result is the high-rate oxidation of odorous molecules.

With this relatively simple but extremely potent technology residual odours may be completely eliminated from the offgas of a wide range of processes. The activated air molecules will attack all oxidisable compounds, reducing them to carbon dioxide, water, nitrogen and other such innocuous substances.

The reactions involved are irreversible.

Key Features

- Highly efficient odour control by means of the high-rate oxidation of target substances.

- Compact, packaged units

- No moving parts and no mechanical wear

- No chemical additions required

- No water consumption

- No waste products

- Low energy requirements

- Minimal maintenance requirements.

Download datasheet

Send download link to:

CH4 Liquefaction

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The liquifaction of methane from biogas, including landfill gas, digester gas, or coal-mine gas provides an opportunity to recover energy from fuel sources that might otherwise be wasted.

Compact gas cleaning and liquefaction systemscan be employed to take such sources and convert them into a cryogenic liquid fuel that may be stored in bulk and dispensed in measured quantities.

The Organics Group offers mobile liquefaction units ranging in size from 2 tonnes per day to up to 10 tonnes per day, a system that is particularly flexible for sources of gas that may be declining or unstable in production.

Specification

Standard mobile units:

2 – 15 tonnes of methane/day (=250 Nm3/hr to 1,750 Nm3/hr)

By-product CO2:

4 – 30 tonnes per day in standard range.

Standard fixed installations:

30 to 400 tonnes of methane/day (=1,750 Nm3/hr to 50,000 Nm3/hr)

By-product CO2:

30 – 800 tonnes per day in standard range.

Download datasheet

Send download link to:

Gas Chillers

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Packaged gas cooling to near-zero or sub-zero temperatures

- Automatic dew-point control

- Fully integrated into system design

- Sub-zero temperatures available

Key Features

A gas chiller can reduce the temperature of a gas stream to around 2ºC. Temperatures below this can also be achieved but will result in freezing of the heat exchanger tubes. Where temperatures of less than zero are required it will be necessary to run tandem heat exchangers, switching the flow from one to the other as they become blocked with ice.

By reducing the temperature to close to freezing point the relative humidity of the gas can also be reduced, thus minimising the possibility of condensate formation in pipes down-stream of the chiller.

Size range

Chiller packages are, as with other items of purpose built process plant supplied by Organics, unlimited in practical size. Flow rates of up to 10,000 Normal cubic metres per hour can be effectively “chilled” to the target levels.

Application

It is often the case that suppliers of certain types of equipment, such as internal combustion engines and gas turbines, will specify a maximum moisture content in the gas to be fed to their plant. The options for dealing with such requirements are limited.

Hydroscopic filters will reduce dew points by up to 6ºC but this may provide inadequate protection, especially as the dew point of the feed gas often varies significantly.

Where properly designed and built a packaged chiller will reliably ensure the target dew point is continuously met.

Download datasheet

Send download link to:

Gas Pumping Sets

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Gas pumping sets for biogas and landfill gas have been supplied by the Organics Group for over thirty years. The technology employed is tried and tested and has been proven under stringent conditions around the world.

The technology is designed to be robust and durable to ensure that down-time is avoided and that regular maintenance schedules can be minimised.

It is well known that biogas, including landfill gas is a unique and complex mixture of elements that, if not carefully monitored, can result in catestrophic damage to sensitive equipment. For this reason, equipment must be built for specific projects and it is rare that two projects are similar in scope.

Specification

The standard scope of supply will includes the following key components:

- Gas blower. Our preference is boosters with back-swept blades that will not surge at low flows.

- Pressure heads are designed to suit individual applications.

- Condensate knockout pot complete with demisting filter and level switching.

- Flame arresters on the inlet and outlet of the gas blower

- Facilities for pressure control to the point of use.

- Optional addition of a low or ultra-low emissions are for continuous relief flaring

- Optional addition of an elevated candlestick flare for site trials and temporary flaring

- Standard instrumentation such as pressure, temperature and flow measurement devices

- Specific instrumentation such as a temperature transducer to detect a flashback at the flame arrester and a motor mounted thermistor to detect overheating

- A range of optional devices such as gas analysers and Internet connection facilities for on-line monitoring are also available.

Download datasheet

Send download link to:

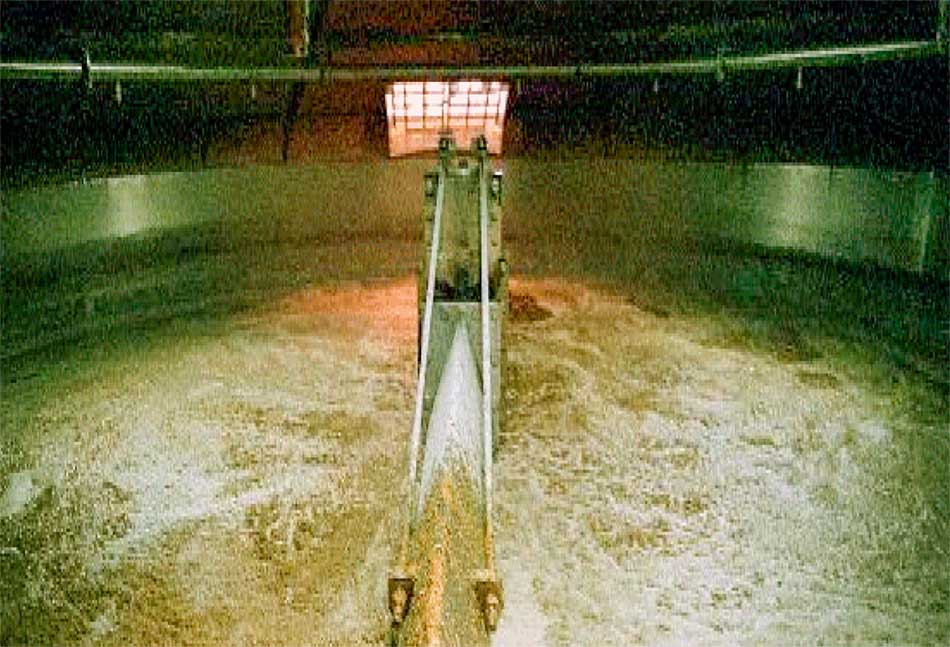

MSW Trommel

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Skid-mounted trommel screens for size separation within the recycling industry. The waste is usually fed into the trommel at a high throughput rate. The trommel then rotates at a slow speed with small particles of waste escaping out of the trommel through the grid.

Larger sized waste continues to pass through the trommel with fines removed. This then separates the waste into specified sizes. These are most commonly used in MRF plants where size separation is an important process to profit from waste. For example, if demolition waste is passed through a trommel screen soil can be reclaimed making it available for reuse enabling customers to profit from waste.

Download datasheet

Send download link to:

Floating decanters

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The floating decanter makes it possible to discharge the upper layer of treated wastewater during the settling stage. A flexible hose and valves connect the floating discharge to the clear water tank or even directly to the public sewer system.

Download our datasheet below.

Download datasheet

Send download link to:

Venturi Aerators

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Aeration is widely used to encourage aerobic micro-organisms to purify effluents biologically. Organics has developed a highly efficient venturi aerator capable of forcing up to 35% of the oxygen from air into true solution.

Significant energy-cost savings can be made by employing this technology when compared to traditional aeration methods.

Download our datasheet below:

Download datasheet

Send download link to:

Eductor Pumps

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Organic s Eductor Pump Sets are generally skid mounted for ease of installation and relocation. Each pump set consists of a priming tank, motive and discharge pumps, a control panel, valved manifolds and piping.

Permanent Eductor Pump Sets are designed and sized on a site-specific basis accordingly to individual requirements. Organics preferred design incorporates both pumps within the priming tank as this provides a more compact unit, and minimizes the risk of pump freezing.

The control panel incorporates the ability to operate the pump set in automatic or manual mode. Hours run meters, and indicator lights displaying the status of the unit and the level of motive fluid in tank are provided for both pumps.

Download datasheet

Send download link to:

Humidifier Evaporators

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Leachate evaporation may be achieved by a number of technologies. These include force-feed reboilers and deep vacuum shell and tube exchangers. An alternative cost-effective approach that may be employed where gaseous high-temperature heat is available, is to pass hot gases directly over the leachate in a humidifier. This approach will result in the leachate being converted to moisture within the gas range.

Download our datasheet below.

Download datasheet

Send download link to:

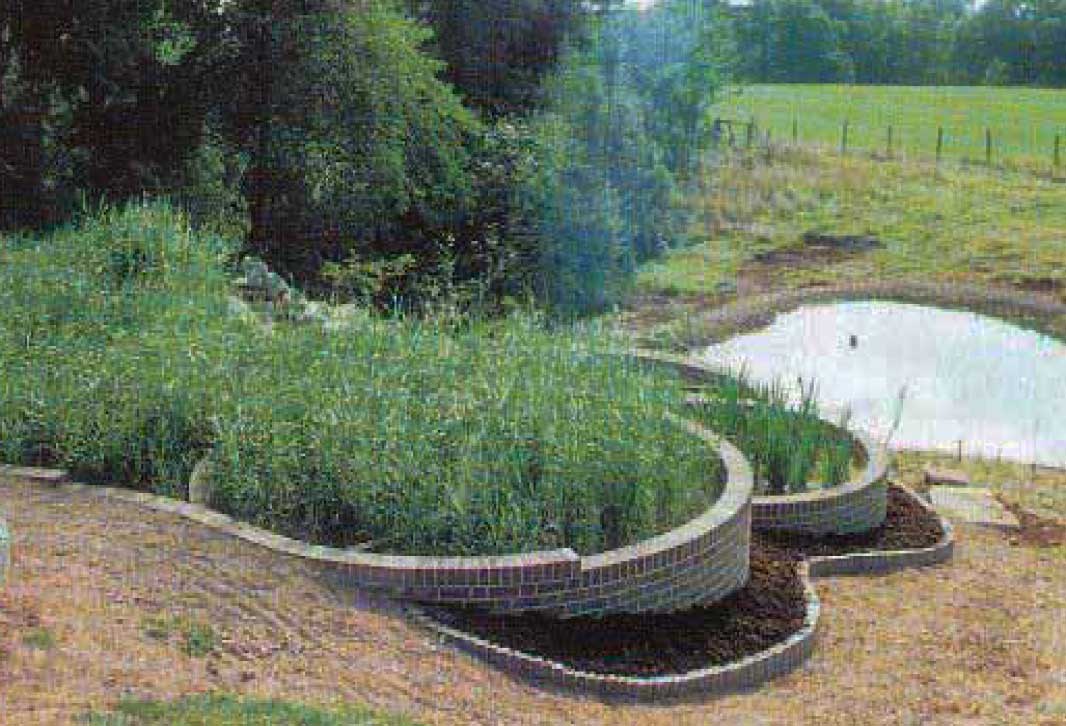

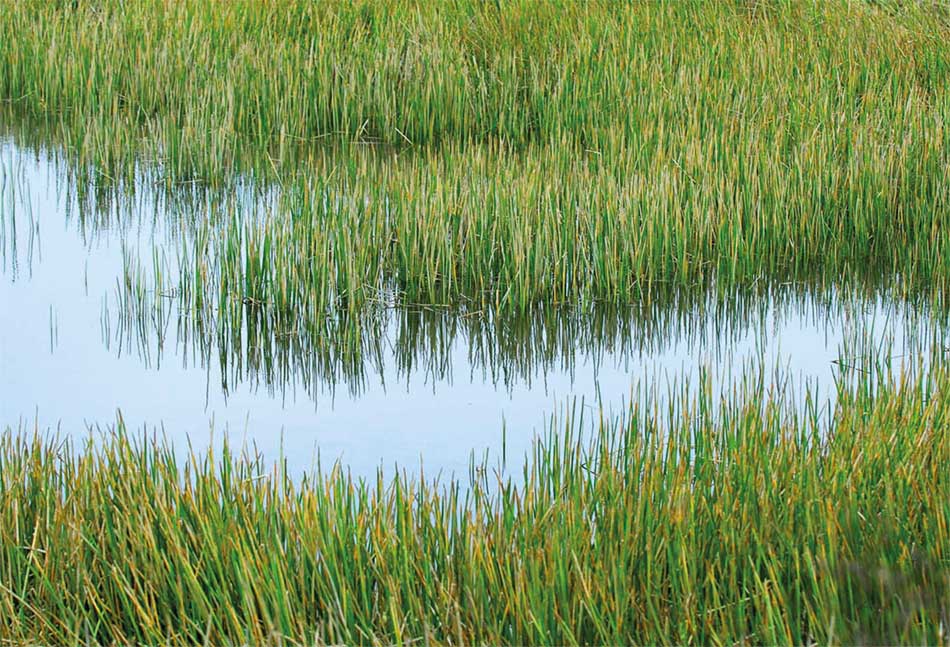

Reed Beds

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

The difference between a ‘natural treatment’ system, such as a reed bed, and a mechanised biological system, such as a sequence batch reactor, is that the former proceeds at a natural rate without the use of significant amounts of energy input. Such systems offer long-term, sustainable treatment of polluted water such as domestic wastewater and landfill leachate.

Download our datasheet below:

Download datasheet

Send download link to:

Treatability Unit

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

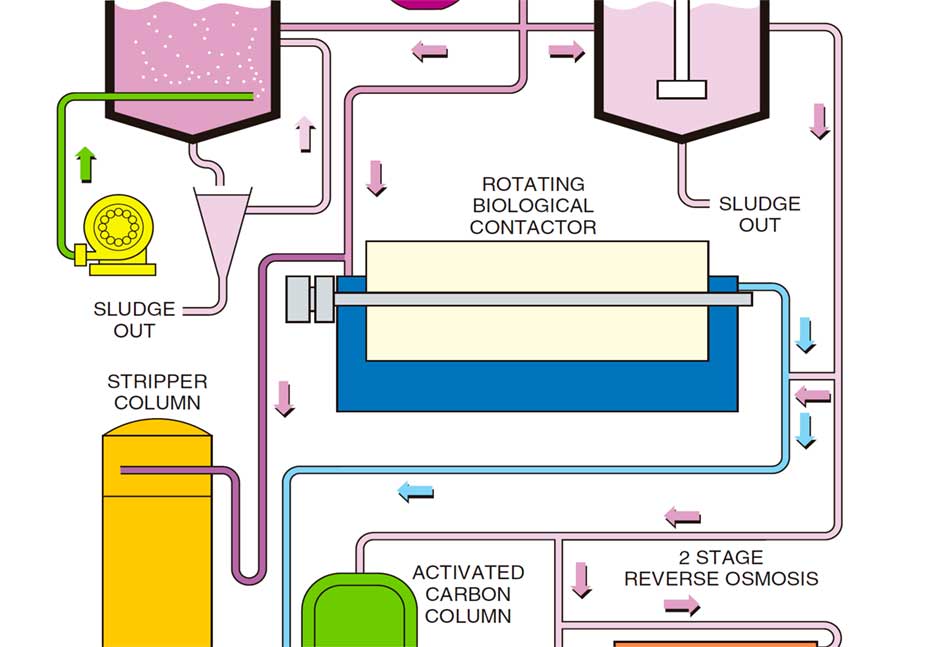

The ideal of testing leachate treatment technologies prior to committing large sums of money, in order to determine which technology is the optimum for any particular leachate, is addressed with the Organics Treatability Unit. This incorporates a fully mixed anaerobic vessel, an aerated chamber, a rotating biological contactor…

Download the datasheet below.

Download datasheet

Send download link to:

Methane Stripping

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Methane may be soluble in domestic wastewater and landfill leachate in concentrations of over 25mg/litre. In practice, it is found that methane may be present at levels in the range of 10-15 mg/litre. A dissolved methane concentration of 1.4 mg/litre has been established as being sufficient to produce an explosive methane level in a confined space.

Download our datasheet below.

Download datasheet

Send download link to:

Pneumatic Pumps

Hidden

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Description

Condensate or total liquid recovery for sampling or extraction purposes.

These units are of simple design and made of strong corrosion resistant materials. The Organics ESI pneumatic pumps have a low air input requirement which is drawn on a demand basis.

Download our datasheet below:

Download datasheet

Send download link to:

LOCATION

TECHNOLOGY

LIFESTYLE

Organics.co.uk is a proud member of the Organics Group of companies. If you would like further information, please

LEGAL STUFF

Organics Privacy Policy

Data Privacy and Protection Policy

SOCIAL MEDIA